To make sure your clients get good results, properly calibrate your broadcast spreaders.

You’ll need an open turf area, tape measure, flags, scale, bucket, calculator, pencil and paper. First, adjust the spreader to the recommended settings on the product’s label.

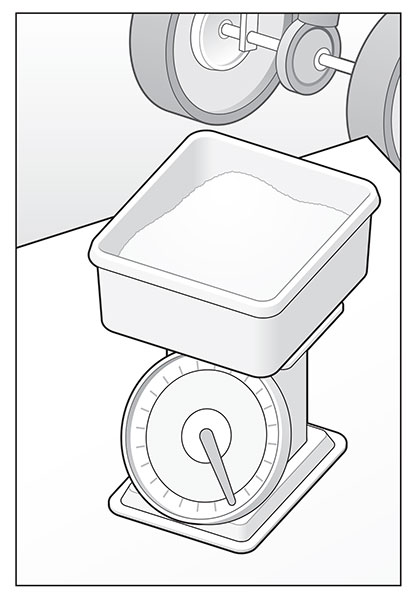

-Place the bucket on the scale, and record its weight. Then, pour the product in the bucket until there is 20 pounds of the product (just as an example). So, if the bucket weighs 2 pounds by itself, the scale will show 22 pounds. With the hopper closed, pour the product into the spreader.

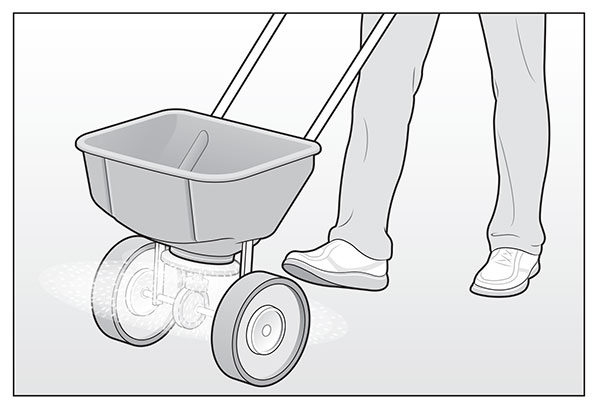

-Measure a 50-foot linear strip of turf, and flag the starting and ending points. Put the spreader a few feet before the starting flag, and walk with it at your normal application pace. Once you reach the start line, open the hopper and continue to walk at that pace. As you pass the end point, close the hopper.

-Pour the remaining product from the hopper into the bucket and weigh it, subtracting the weight of the bucket. Then, subtract that number from 20 (your original quantity) to get the amount of product used. Also, measure the spread width.

-For this example, the fertilizer is 20-10-10 (N-P-K), and the application rate is 1 pound N per 1,000 square feet. Turn the N into a percentage, so it would be 20 percent (0.20). To see how much fertilizer you need to apply 1 pound of N per 1,000 square feet, use Formula 1 (at right).

-Now, determine the product weight that must be applied during the test run to have the spreader deliver 5 pounds per 1,000 square feet. Say the spreader used 2 pounds during the test with a spread width of 12 feet. Multiply the spread (12) by the strip length (50), and you have a 600-square-foot test area. Then, plug the numbers you have into Formula 2 (at right). If not enough of the product was applied (like in this example, since we had 2 pounds used), adjust the hopper openings. Repeat the test until you get the correct result.

Step 1

Weigh the product in a bucket and pour it into the hopper, with the spreader set to the product’s recommended settings.

Step 2

Push the spreader 50 feet with the hopper in the open position, and close it after walking that distance at your normal pace. Pour the remaining product back into the bucket on the scale.

Step 3

Use these two formulas to see if you need to increase or decrease the amount of product being applied, and adjust the hopper openings accordingly:

Formula 1: Pound of N per 1,000 square feet (1) ÷ percentage of N in product (0.20) = pounds of product per 1,000 square feet (5)

Formula 2: Pounds of product per 1,000 square feet (5) x test area (600) ÷ 1,000 square feet = weight of product needed to be applied in test run (3 pounds)

Sources: Penn State & University of Minnesota Extensions

Illustrations: David Preiss